News Release

News Release

-

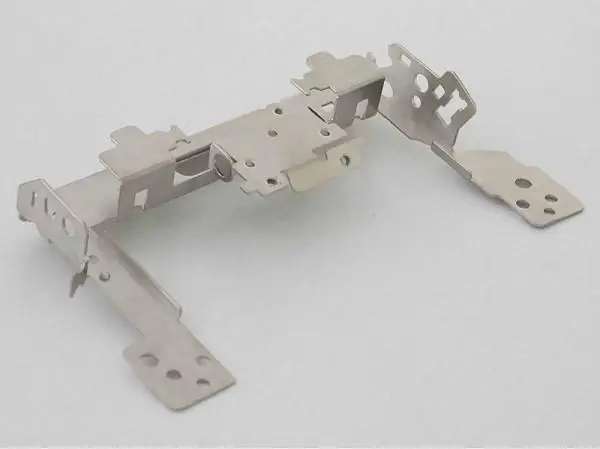

Research on the Development Trends and Investment Risks of 2023 Automotive Stamping Parts Industry

There are many kinds of automobile stamping parts, and the market space is large, but the market is relatively scattered, and the industry concentration ratio is low. From the perspective of market st...

Processability of stretched parts

The following is Nanpi Zhongchi Hardware Manufacturing Co., Ltd.'s analysis of the processability of stretching parts for you

1. The shape of the drawn part should be as simple and symmetrical as possible, and it should be formed in one deep drawing as much...

-24

2023-5

MORE

Common issues with stamping parts

Stamped parts may encounter some problems during use. Today, we will introduce the problems that mold parts may encounter during the stamping process

1. Convex and concave: foreign objects (iron filings, dust) mixed into the uncoiling line, causing convexit...

-23

2023-5

MORE

Tensile depth distribution of each sequence of tensile parts

Try to use large gap punching as much as possible based on the specific situation, while ensuring that the workpiece does not experience edge collapse; The straightening process should be "straightened" rather than "smashed straight"; The drawing depth distrib...

-22

2023-5

MORE

What precautions should be taken when designing stretching parts

Precautions for dimensioning on the design drawings of stretched parts: Due to the varying magnitude of stress applied to each part, the material thickness after stretching changes. Generally speaking, the bottom center maintains the original thickness, the ma...

-21

2023-5

MORE

Defective phenomena and reasons in material processing of stamping parts

The main reasons for the occurrence of scratches, indentations, or deformation of rounded corners during the production of various stamping products are as follows

1、 Firstly, let's take a look at the stamping process: During the stamping process, if the op...

-21

2023-5

MORE

Zhongchi Hardware analyzes the processability of stretched parts for you

Nanpi Zhongchi Hardware Manufacturing Co., Ltd. analyzes the processability of stretching parts for you

The structural craftsmanship of deep drawn parts: 1. The shape of deep drawn parts should be as simple and symmetrical as possible, and should be formed ...

-19

2023-5

MORE

Why do some stretching parts need to be stretched multiple times?

Why do some stretching parts need to be stretched multiple times?

1. Multiple stretching can greatly improve the overall elongation coefficient and production efficiency, and ensure the accuracy of the product through multiple uniform stretching processes

...

-18

2023-5

MORE

Common problems in the process of making stamping parts molds

The main function of molds is to produce more consistent products, and the processing stability during the production process is an important factor to consider. Below, let's take a look at the common problems that stamping parts molds often encounter during t...

-18

2023-5

MORE

What are the requirements for stamping materials during the stamping process

Stamping materials must not only ensure strength, stiffness and other performance, but also meet the requirements of stamping technology

The quality of materials directly affects the design of stamping process, mold design, mold service life, quality and se...

-17

2023-5

MORE

Classification of Spring Raw Materials

Spring raw materials are divided into two parts: metallic materials and non-metallic materials.

Metal materials include:

1. Spring steel - carbon spring steel and alloy spring steel;

2. Special bead elastic materials - stainless steel, iron based elas...

-16

2023-5

MORE

Method for checking whether the surface of the spring is clean

1. Paint method

Drop the degreaser onto the surface of the spring and evaporate to dryness. If there are no traces, the surface of the spring is clean. If a circular ring appears, it indicates the presence of oil stains.

2. Moisturizing method

A clean...

-16

2023-5

MORE

Principles for designing stamping parts

The designed stamping parts, while ensuring normal use, should strive to lower the requirements for dimensional accuracy and surface roughness levels, and facilitate product interchangeability, reduce waste, and ensure stable product quality. The first step in...

-15

2023-5

MORE

The relationship between automobiles and stamping parts

The automobile factory has four major processes: stamping workshop, welding workshop, painting workshop, and final assembly workshop. Automotive stamping parts are produced in stamping workshops. Let me give you an example. All the metal shells you see on car ...

-15

2023-5

MORE

Stamping parts manufacturing process

Stamping processing is a production technology that utilizes the power of conventional or specialized stamping equipment to directly deform the sheet metal in the mold, thereby obtaining a certain shape, size, and performance of product parts. Sheet metal, mol...

-15

2023-5

MORE

Dimensional tolerances and quality of stamped parts

The forming and processing method of obtaining the required shape and size of workpieces by applying external forces to plates, strips, pipes, and profiles through punches and molds, resulting in plastic deformation or separation. The resulting workpieces are ...

-13

2023-5

MORE

How to select materials in stamping parts

Due to the fact that the operation of the elastic unloading mold is more convenient than the fixed unloading mold, the operator can see the feeding action of the strip in the mold, and the elastic unloading plate applies flexible force to the strip during unlo...

-12

2023-5

MORE